With the rapid development of modern power semiconductor technology, the performance of silicon-based power semiconductor devices has approached its material limit. As a mainstream silicon-based power switching device, Si IGBT has the advantages of low conduction loss and low cost. However, high switching loss limits its application in high switching frequency and high power density converters.

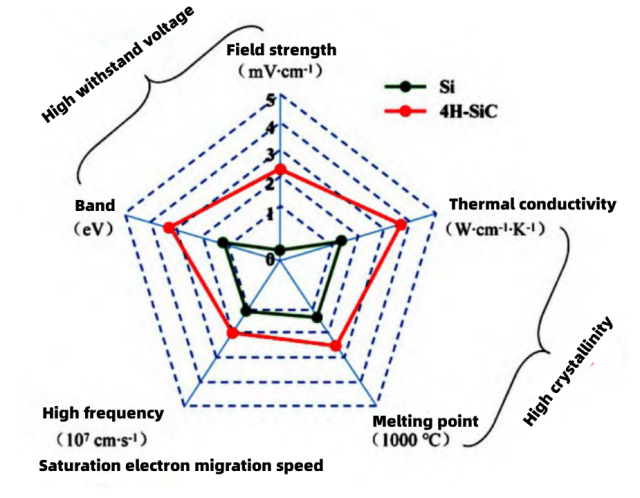

As the next generation semiconductor material recognized worldwide as a substitute for silicon, silicon carbide material has the advantages of large bandgap, high breakdown field strength, high saturation drift rate and high thermal conductivity. It is more suitable for high temperature, high pressure and high power fields.

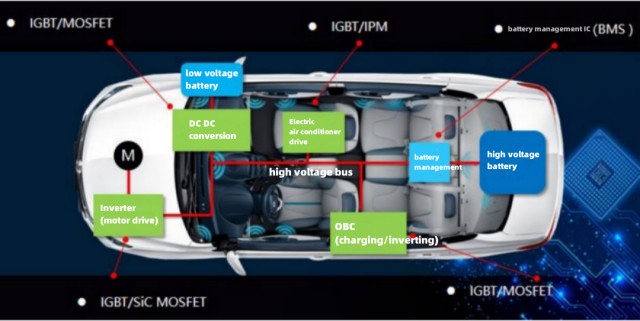

Among them, the most representative SiC MOSFET device has extremely low on-resistance, faster switching speed, lower switching loss and higher breakdown voltage. SiC MOSFET can significantly improve the efficiency and power density of power electronic converters. It makes it easier for the electric energy converter to be miniaturized, lightweight, and more resistant to high temperature and high pressure. It has broad application prospects in new energy and hybrid vehicle applications.

So, can SiC MOSFET replace Si IGBT? What is the difference between them? This article combines the technological development of these two power semiconductors and compares the differences, advantages, disadvantages, application directions and technical challenges faced by each to help you quickly understand and correctly choose the corresponding solution based on the characteristics of your project.

article outline

Development bottlenecks of Si IGBT

Compared with Si IGBT, what are the advantages of SiC Mosfet?

Can SiC Mosfet completely replace Si IGBT?

Compared with Si IGBT, what are the disadvantages of SiC Mosfet?

What is Si IGBT?

Since the advent and application of thyristors and power transistors, with the continuous improvement and improvement of Si-based devices, power transistors (GTR), gate-turn-off thyristors (GTO), and metal-oxide semiconductor field-effect transistors (MOSFETs) have appeared one after another. and power electronic devices such as insulated gate bipolar transistors (IGBTs). Compared with other Si-based power devices, Si IGBT is a composite fully controlled voltage-driven power device composed of two structures: BJT and MOSFET. This power device not only has the advantages of large current capacity, reduced conduction voltage and low cost, but also At the same time, the driving power is small and the driving control circuit is simple. Therefore, this power device has been widely used in different converters.

Market size of Si IGBT

Data research from The Business Research Company points out that the global Si IGBT market size will grow from US$7.27 billion in 2022 to US$8.42 billion in 2023, with a CAGR of 15.7%, and will grow to US$15.27 billion by 2027, with a CAGR of 16.0% . From the perspective of Si IGBT upstream manufacturers, nearly 70% of the global Si IGBT market is currently occupied by companies such as Infineon, Mitsubishi Electric, Fuji Electric, ABB, and ON Semiconductor. From the perspective of Si IGBT downstream application fields, new energy vehicles, consumer electronics and industrial control account for a total of 78%, and the three major industries account for 31%, 27% and 20% respectively. Among them, new energy vehicles, in particular, are the main driving force for the rapid growth of the Si IGBT market.

Development bottlenecks of Si IGBT

However, in recent years, limited by the theoretical performance limit determined by the characteristics of Si material, the development of Si IGBT has encountered bottlenecks, mainly in the following aspects:

①Affected by the tail current, the switching speed is limited. Although the internal structure of Si IGBT is continuously optimized to effectively improve its switching speed, due to the influence of the tail current when the power device is turned off, the improvement of its turn-off speed is still limited, which means that the Si IGBT turn-off loss cannot be effectively decrease.

②In the high power range, the on-resistance changes greatly. Since Si IGBT has characteristics similar to those of PN junction when conducting forward, this power device cannot maintain low on-resistance in a wide power range, especially when the power level is low, the conduction of Si IGBT The loss is relatively large.

③Affected by the junction temperature of the device, the on-resistance changes greatly. Since Si IGBT has a positive temperature coefficient characteristic, its internal on-resistance increases as the junction temperature increases. Therefore, when the power device operates at a higher junction temperature, the loss is larger.

In summary, the low switching speed and high power loss of Si IGBT limit the further reduction of the passive filter and heat sink in the inverter, making it difficult for the device to meet the application requirements for higher efficiency and power density. Especially in the field of new energy vehicles, traditional Si IGBT chips have reached the physical limits of materials in high-voltage fast-charging models, so new energy vehicles have begun to embrace SiC.

Compared with Si IGBT, what are the advantages of SiC Mosfet?

① Higher thermal conductivity makes it easier to dissipate heat, making SiC MOSFET have higher operating temperature characteristics than Si IGBT, that is, the stability is significantly improved during high-temperature operation.

②The higher electron saturation speed makes the SiC MOSFET have lower on-resistance within the range of large junction temperature changes and power changes, so the power device has low conduction loss.

③Higher electron mobility enables SiC MOSFET to have faster switching speed, so the operating frequency of the power device can be higher.

④The wider bandgap enables SiC MOSFET to have higher voltage withstand capability.

sic mosfet advantage

Based on the above advantages and with the continuous improvement of silicon carbide device manufacturing technology, the price of SiC MOSFET has dropped significantly. Therefore, SiC MOSFET has gradually been promoted to photovoltaic inverters, electric vehicles, power supplies, base station communications, rail transit and other applications. field.

According to TrendForce research statistics, the top two applications of SiC power components are in the fields of electric vehicles and renewable energy, which will reach US$1.09 billion and US$210 million respectively in 2022, accounting for approximately 67.4% and 13.1% of the overall SiC power component market output value. With the clarification of cooperation projects between ON Semiconductor, Infineon and other automotive and energy companies, the overall SiC power component market output value will reach US$2.28 billion in 2023, with an annual growth of 41.4%. By 2026, the SiC power component market output value is expected to reach US$5.33 billion. Mainstream applications still rely on electric vehicles and renewable energy. The output value of electric vehicles can reach US$3.98 billion, with a CAGR of approximately 38%; renewable energy can reach US$410 million, with a CAGR of approximately 19%.

Can SiC Mosfet completely replace Si IGBT?

The answer is no. Although SIC Mosfet is developing rapidly, Si IGBT has experienced a development bottleneck. However, there are still some problems with SiC MOSFET at this stage, which not only prevents it from effectively shaking the dominant position of Si IGBT as a power device, but also limits the large-scale industrial promotion and application of SiC MOSFET.

Compared with Si IGBT, what are the disadvantages of SiC Mosfet?

① Due to the high defect density of SiC materials, SiC device design and process maturity, low product yield and reliability, the rated current of single-chip SiC MOSFET is much smaller than the rated current of single-chip Si IGBT, which limits the SiC MOSFET Moving towards higher power levels. Currently, Rohm Semiconductor Group’s commercial 1200V SiC MOSFET (SCT3022KLHR) has a maximum current-carrying capacity of 95A, and a commercial 650V SiC MOSFET (SCT3017AL) has a maximum current-carrying capacity of 118A; Cree’s commercial 1200V SiC MOSFET ( C3M0016120D) discrete device has a maximum current carrying capacity of 115A, commercial 650V SiC MOSFET (C3M0015065D) discrete device has a maximum current carrying capacity of 120A; Infineon’s commercial 1200V Si IGBT (IKY75N120CH3) discrete device has a maximum current carrying capacity of up to The maximum current carrying capacity of the 150A, 650V Si IGBT (IGZ100N65H5) discrete device can reach 161A. In fact, the current carrying capacity gap between the two types of power modules is even greater. The current carrying capacity of the Si IGBT module exceeds the current carrying capacity of the SiC MOSFET module by more than 5 times.

②The long-term operation reliability of SiC MOSFET is still worse than that of Si IGBT, which limits the application of this power device in the field of high-reliability power conversion. Compared with Si IGBT, SiC MOSFET is mainly reflected in its short-circuit capability and insufficient reliability of gate oxide under high temperature and strong electric field.

③ Affected by factors such as high SiC material cost, complex device manufacturing process and low product yield, the cost of SiC MOSFET still has a large gap compared with similar Si IGBT discrete devices, which hinders the large-scale industrialization of SiC devices promotion. The unit price of SiC MOSFET discrete devices is 3 to 15 times the cost of Si IGBT discrete devices, and with the improvement of current carrying capacity, the price gap is getting wider and wider.

④The switching speed of SiC MOSFET is faster, which means that the power device will generate higher dv/dt and di/dt during the switching process, which will generate more serious conducted EMI noise and threaten the performance and reliability of the converter. Therefore, the use of SiC MOSFET will put forward higher requirements for the suppression of EMI noise of the converter.

Based on the above characteristics, SiC MOSFETs are not suitable for some low-cost, low-power application scenarios. Therefore, it is very difficult to completely replace Si IGBTs with obvious cost advantages. In addition, with the advancement of packaging technology, the performance and power density of Si IGBT devices are getting higher and higher. At the same time, products developed for different applications can be specially optimized to improve the performance of Si devices in the system, thereby further improving system performance and cost performance.

In conclusion

In the dynamic world of power electronics, the choice between SiC MOSFETs and Si IGBTs depends on various factors such as application requirements, performance goals and budget considerations. Both technologies have their benefits and challenges, and as the field of power electronics evolves, so will the capabilities of SiC MOSFETs and Si IGBTs. SiC MOSFETs shine due to their high-speed switching, lower losses, and potential for increased power density, making them suitable for high-frequency and high-efficiency applications. Si IGBTs, on the other hand, excel in applications requiring high voltage and current handling capabilities, striking a balance between switching speed and efficiency.

Need Help?

Need Help?